Continuous improvement of processes, products, and services

Efficiency based on process automation is error-prone and at the same time allows experienced and talented employees to focus on activities with higher added value, informative analysis and a team of emerging innovations and better business results.

Continuous Improvement focuses on the efficient running of processes and the implementation of only those activities that bring additional added value. On the other hand, it excludes two activities that do not add value. There is a need to reduce waste and improve value for customers. The method is based on the ability to do more with fewer resources, with the help of constant elimination of waste. Products and services are concentrated in the right quantity and condition, at the right time and in the right place.

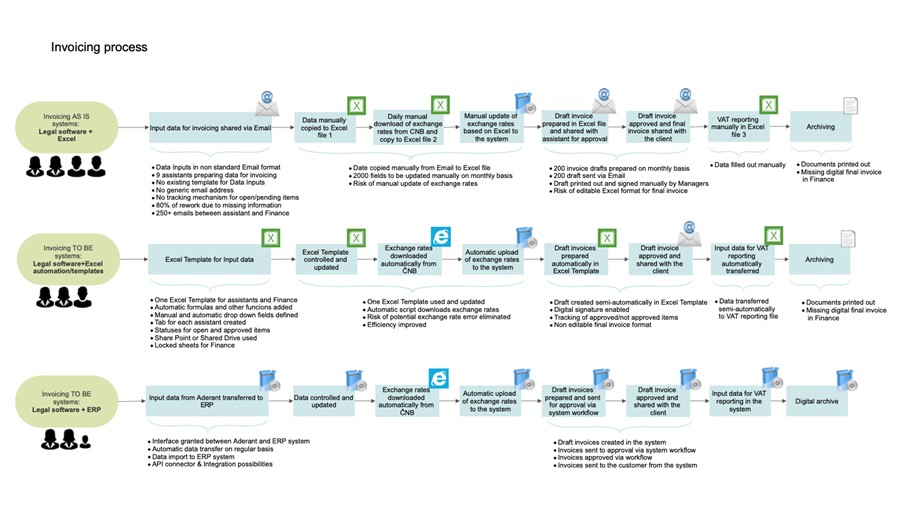

The first step on the road to further improvement is to identify those processes that can be automated. These speeds up processes, reduces the time spent on manual processes and maintains high quality while reducing the error rate that is often associated with manual work. We will give you instructions on how to improve the performance of your organization by identifying activities that don’t add value.